Disposable Paper Tea Coffee Milk Cup Forming Machinery

Peb cov khoom tau lees paub thiab ntseeg tau zoo heev los ntawm cov neeg siv khoom thiab tuaj yeem ua tiav ntau zaus hloov pauv nyiaj txiag thiab kev xav tau rau Disposable Paper Tea Coffee Milk Cup Forming Machinery, Peb zoo siab tos txais ib qho kev cia siab los ua lag luam nrog koj thiab vam tias yuav muaj kev txaus siab rau txuas ntxiv cov ntaub ntawv ntawm peb cov khoom.

Peb cov khoom tau lees paub thiab ntseeg tau zoo los ntawm cov neeg siv khoom thiab tuaj yeem ua tiav kev hloov pauv nyiaj txiag thiab kev xav tau ntawm tib neegTuam Tshoj Paper Cup Ua Tshuab, Daim ntawv khob txoj kev tshuab, Peb lub tuam txhab npog thaj tsam ntawm 20, 000 square meters. Tam sim no peb muaj ntau tshaj 200 tus neeg ua haujlwm, pab pawg tsim nyog, 15 xyoo kev paub, kev ua haujlwm zoo, ruaj khov thiab txhim khu kev qha zoo, tus nqi sib tw thiab muaj peev xwm ntau lawm, qhov no yog qhov peb ua rau peb cov neeg siv khoom muaj zog. Yog tias koj muaj lus nug, nco ntsoov tias koj tsis yig tiv tauj peb.

Specification ntawm Tshuab

| Specification | CM 100 |

| Standard Machine Configuration | Extended magazine rau nws pib daim ntawv dawb paug pubFinished khob suav thiab nesting tableOne txheej txheej pwm rau ib khob loj |

| OptionalEquipment | In-line khob tshuaj xyuas system |

| Daim ntawv khob loj ntawm kev tsim khoom | 2oz ~ 32oz |

| Ntau lawm ceev | 120-150 pcs / min |

| Sab sealing txoj kev | Leisterhot cua cua sov & ultrasonic |

| Hauv qab sealing txoj kev | Leisterhot cua cua sov |

| Rated zog | 21 kWm |

| Kev siv cua (ntawm 6kg / cm2) | 0.4 m³ / min |

| Zuag qhia tag nrho Dimension | L2,820mm x W1,300mm x H1,850mm |

| Tshuab nqa hnyav | 4, 200 kg |

Cov khoom tiav

★ Sab saum toj Dia: 45 - 105mm

★ Hauv qab Dia: 35 - 78mm

★ Tag Nrho Qhov siab: siab tshaj 137mm

★ Lwm qhov ntau thiab tsawg yog thov

Muaj ntawv

Ib leeg PE / PLA, Ob chav PE / PLA, PE / Aluminium los yog dej-raws li barrier coated ntawv board

Competitive Advantage

REASSONABLE TRANSMISION DESIGN

❋ Lub tshuab xa hluav taws xob feem ntau yog los ntawm lub zog mus rau ob lub qhov ntev. Lub ntsiab lub cev muaj zog cov zis yog los ntawm ob sab ntawm lub cev muaj zog ncej, yog li lub zog xa mus yog sib npaug.

❋ Cov qauv xa tawm yog tsim nyog, yooj yim thiab siv tau, tawm hauv chav txaus rau kev kho thiab tu.

❋ Qhib hom indexing iav (turret 10 : turret 8 kev npaj ua kom txhua txoj haujlwm tsim nyog). Peb xaiv IKO (CF20) hnyav load pin cov menyuam bearing rau indexing iav cam follower, roj thiab cua siab ntsuas, cov transmitters yog siv (Nyiv Panasonic).

HUMANIZED SRUCTURE DESIGN

❋ Lub rooj noj mov yog ob lub lawj tsim los tiv thaiv daim ntawv plua plav mus rau hauv lub ntsiab ncej. Lub rooj yog tsim los nrog qhov dav tsim nyog, uas yooj yim dua rau kev saib xyuas.

❋ Qhov thib ob turret nruab nrog 8 chaw ua haujlwm. Yog li cov haujlwm ntxiv xws li qhov chaw nres tsheb thib peb (rau qhov zoo dua rim dov) lossis qhov chaw nres tsheb grooving tuaj yeem pom tau.

❋ Folding tis, knurling wheel thiab brim rolling stations yog adjustable saum lub rooj loj, tsis muaj kev hloov kho nyob rau hauv lub ntsiab ncej kom ua hauj lwm yooj yim dua thiab txuag sij hawm.

ELECTRICAL COMPONENTS CONFIGURATION

❋ Hluav taws xob tswj txee: Tag nrho lub tshuab yog tswj los ntawm PLC, peb xaiv Nyiv Mitsubishi high-end khoom. Tag nrho cov motors yog ywj siab tswj los ntawm zaus invertors, cov no tuaj yeem hloov kho ntau yam ntawm daim ntawv cim.

❋ Heaters siv Leister, uas yog lub npe nrov hauv Swiss, ultrasonic rau sab seam supplemental.

❋ Daim ntawv qib qis lossis daim ntawv ploj lawm thiab daim ntawv-jam thiab lwm yam, tag nrho cov kev ua txhaum no yuav pom meej hauv lub qhov rais kov lub tswb.

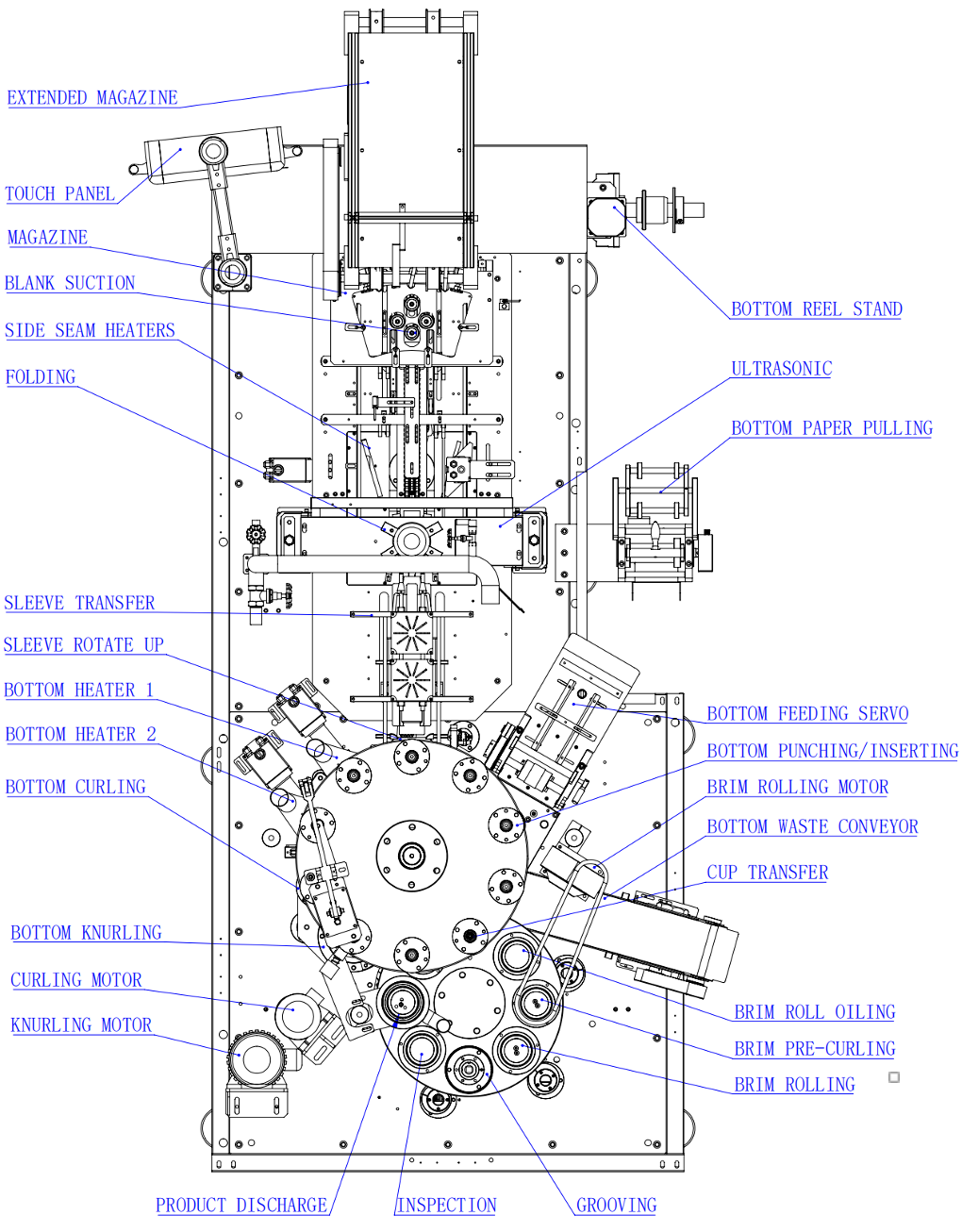

Cov kauj ruam ua haujlwm tshuab

Daim ntawv blanks pub → sab-seam cua sov → folding & sealing → khob lub tes tsho hloov → hauv qab sib sau & inserting → txiv neej mandrel → hauv qab cua sov 1 → hauv qab cua sov 2 → hauv qab oiling → hauv qab curling → hauv qab knurling → semi-product hloov → khob rim oiling → rim khob curling 1 m pawg

yees duab

Peb cov khoom tau lees paub thiab ntseeg tau zoo los ntawm cov neeg siv khoom thiab tuaj yeem ua tiav kev hloov pauv nyiaj txiag thiab kev sib raug zoo rau tus nqi qis tshaj Tuam Tshoj Pov Tseg Nqe ntawm Ntawv Tea Coffee Milk Cup Forming Machinery, Peb zoo siab tos txais ib qho kev cia siab ua lag luam nrog koj thiab vam tias yuav muaj kev txaus siab rau kev txuas ntxiv cov ntaub ntawv ntxiv ntawm peb cov khoom.

Tus nqi qis tshaj plawsTuam Tshoj Paper Cup Ua Tshuab, Daim ntawv khob txoj kev tshuab, Peb lub tuam txhab npog thaj tsam ntawm 20, 000 square meters. Tam sim no peb muaj ntau tshaj 200 tus neeg ua haujlwm, pab pawg tsim nyog, 15 xyoo kev paub, kev ua haujlwm zoo, ruaj khov thiab txhim khu kev qha zoo, tus nqi sib tw thiab muaj peev xwm ntau lawm, qhov no yog qhov peb ua rau peb cov neeg siv khoom muaj zog. Yog tias koj muaj lus nug, nco ntsoov tias koj tsis yig tiv tauj peb.